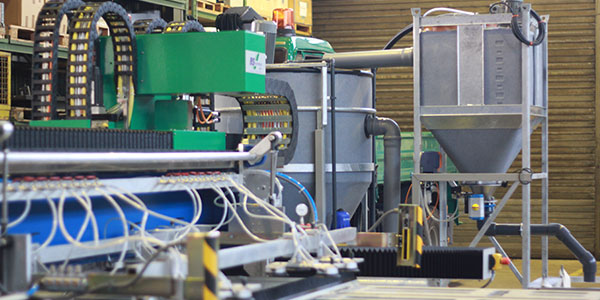

Monitored water quality for durability, productivity and environmental protection

Particularly in the glass processing area, the grinding dust is a serious stress on the systems and on the environment. There is immense potential for saving here, if only in the considerable reduction of maintenance and down time.

No more glass sludge deposits in the machinery caused by carried flocculant material. The system is designed for the use of cooling lubricant.

Intelligent linking of the measurements in the system controller leads to reduced cycle times and avoids flocculant consumption. Not only can the size of the system be reduced, but also the consumption of energy and flocculant. This protects the environment and the budget.

Our patented water treatment saves you working time and reduces the everyday use of operating materials. The system that has been dimensioned for you therefore operates independently and autonomously for many days.

Fresh water saving of up to 80%

Fresh water saving of up to 80%

Low material use (flocculant and fresh water), together with a minimum

of waste disposal, filling and cleaning times

System pays for itself within 12 months (depending on use)

- Minimal maintenance cost

- Minimal cleaning cost

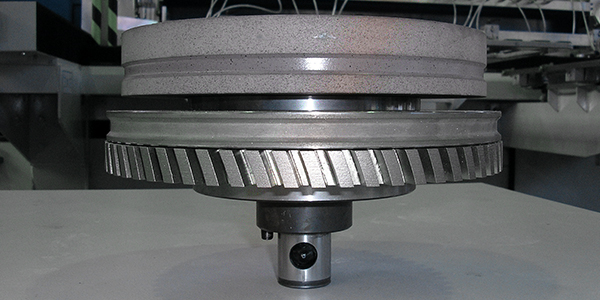

- Minimal wear

- Minimal grinding system wear

- Up to 80% less fresh water consumption

- More quality, productivity and capacity

Due to an independently operating preparation and dosing, plus extremely simple sludge disposal

We not only reduce the wear on grinding and polishing tools, but also the use of abrasives.

Increased production safety more profit for your company and the environment gains too

- Safe supply of clean cooling water

- Sensible use of cooling lubricants

- Improved glass edge quality together with longer tool life

- Definite reduction of maintenance costs for your glass processing machines

- Minimal cleaning expenditure for RS glawaclean and the connected processing machines

- Definite savings on machine repairs / less wear

- The lowest possible water and waste water costs

- Decreased costs for washing the glass pieces

- Our profit check shows: Amortisation is possible in less than 12 months