Complete processing from flat glass to high-quality shaped glass

Unlimited Possibilities

Multi-channel cooling and high-performance spindles for tools ranging from 3 mm to 200 mm, with speeds of up to 24,000 RPM.

Highest Productivity

Maximum performance and superior quality for optimal efficiency in flat glass processing.

Reliable and Durable

Consistent production with stable quality for long-term reliability.

Our Machines

Whatever You Need – We Serve It Best

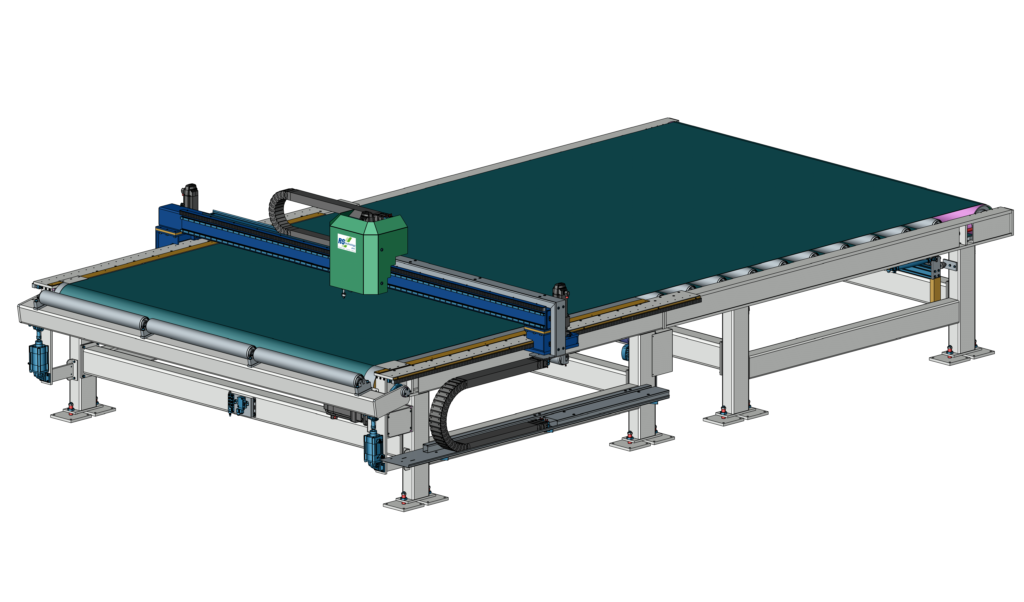

CNC Cutting

Technical Data

| RS 7.51 | RS 7.53 | RS 7.55 | ||

| Max Glass Table Size | 3,3 x 6,3m | 2,55 x 3,3m | 1,6 x 2,5m | |

| Glass Thickness (Min to Max) | 2 – 19 25 | min 0,7 | ||

| Cutting Weight | ||||

| Acceleration | ||||

| Tolerance up to 1000 mm | ±0,15 | optional ≤ ±0,1 | ||

| Cutting Accuracy | Alternating closed or open cuts up to ≈ 8mm thickness | |||

| Glass Support | Closed transport panel, CNC controlled on solid steel plate | |||

| Cutting Pressure | ||||

| Cutting Oil / SR Change | < 5 sec | |||

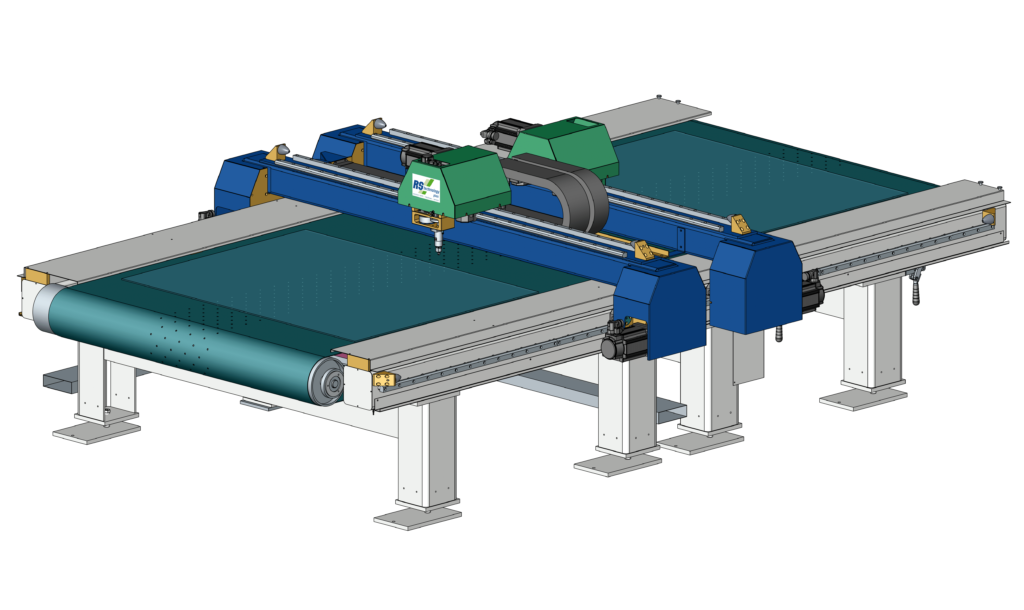

CNC Cutting - Breaking

Technical Data

| RS 7.51 | RS 7.53 | RS 7.55 | ||

| Max Glass Table Size | 3,3 x 6,3m | 2,55 x 3,3m | 1,6 x 2,5m | |

| Glass Thickness (Min to Max) | 2 – 19 25 | min 0,7 | ||

| Cutting Weight | ||||

| Acceleration | ||||

| Tolerance up to 1000 mm | ±0,15 | optional ≤ ±0,1 | ||

| Cutting Accuracy | Alternating closed or open cuts up to ≈ 8mm thickness | |||

| Glass Support | Closed transport panel, CNC controlled on solid steel plate | |||

| Cutting Pressure | ||||

| Cutting Oil / SR Change | < 5 sec | |||

CNC Ball Cutting

Technical Data

| RS 7.51 | RS 7.53 | RS 7.55 | ||

| Max Glass Table Size | 3,3 x 6,3m | 2,55 x 3,3m | 1,6 x 2,5m | |

| Glass Thickness (Min to Max) | 2 – 19 25 | min 0,7 | ||

| Cutting Weight | ||||

| Acceleration | ||||

| Tolerance up to 1000 mm | ±0,15 | optional ≤ ±0,1 | ||

| Cutting Accuracy | Alternating closed or open cuts up to ≈ 8mm thickness | |||

| Glass Support | Closed transport panel, CNC controlled on solid steel plate | |||

| Cutting Pressure | ||||

| Cutting Oil / SR Change | < 5 sec | |||

3 Different Machining Centers

For the complete processing of your glass products

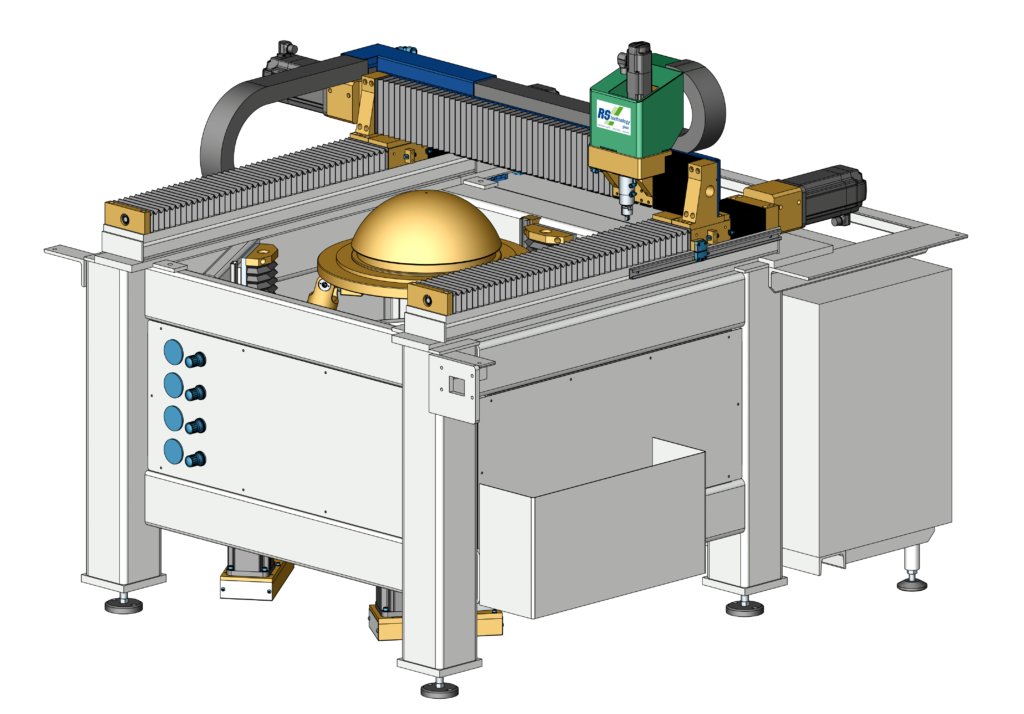

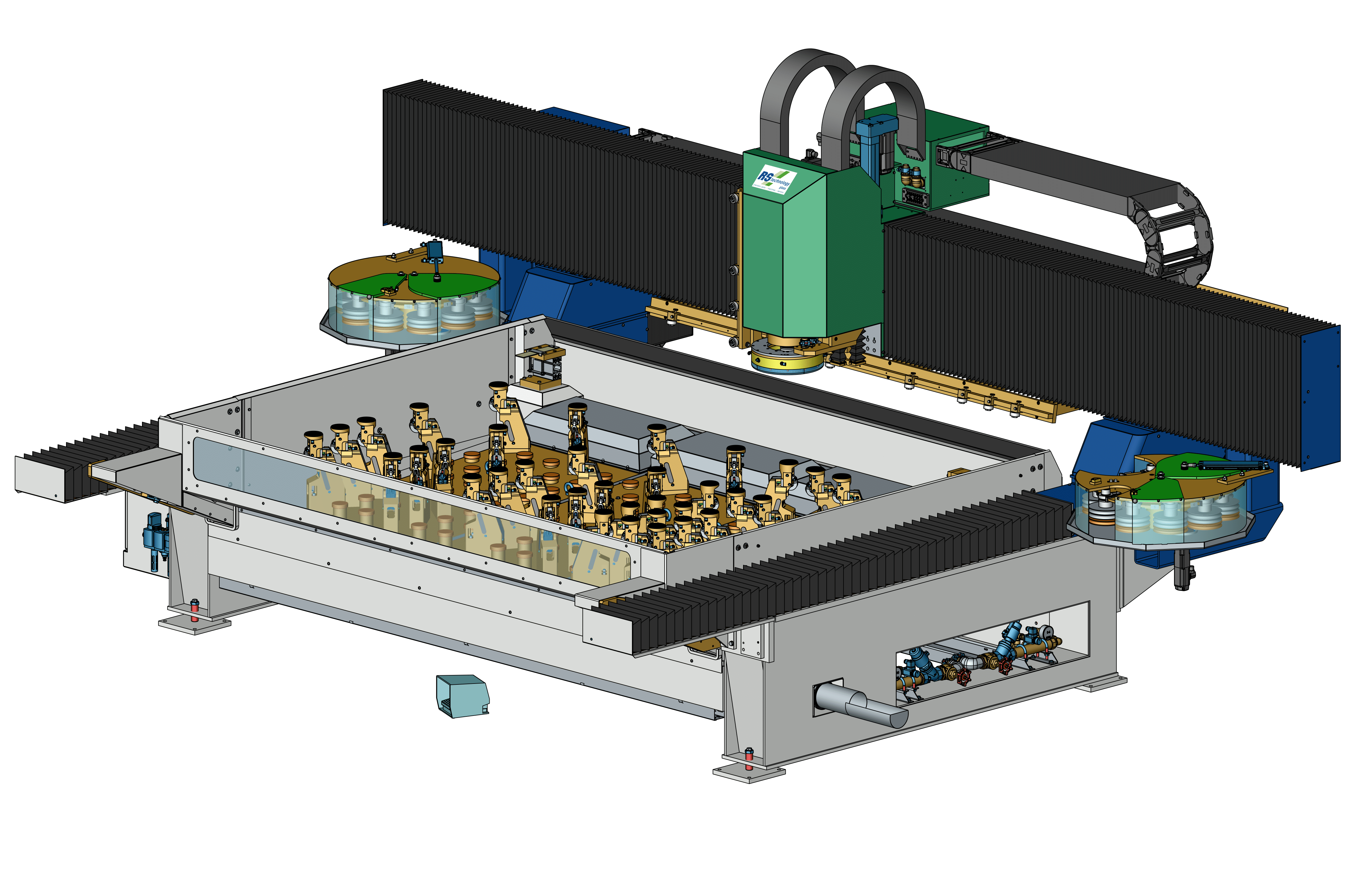

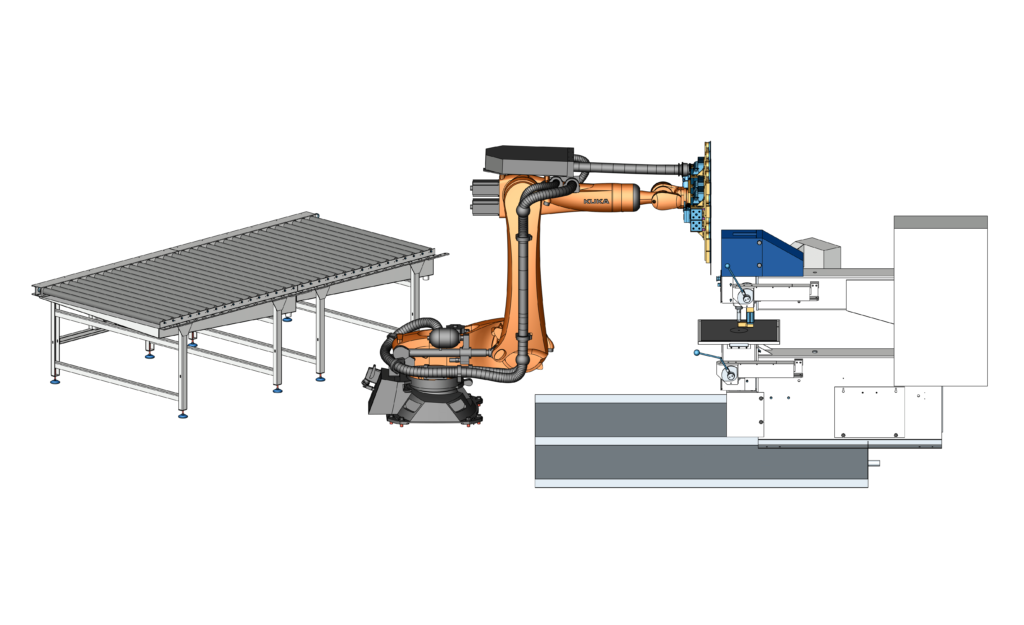

MC with Traveling Bridge

RS 89.07 VSS – Maximum Flexibility with Highest Automation

The RS 89.07 VSS is our top model, designed for small-series production and single-piece manufacturing with zero setup time, fully automated and “manless,” requiring no skilled labor!

Technical Data

| Feature | Specification |

| Number of Grinding Heads | 1 |

| Min. Glass Size | 250 x 90 mm, smaller sizes upon request |

| Max. Glass Size | 2500 x 1500 mm with tool max. Ø 150 mm |

| Glass Thickness | 1.2 to 19 mm |

| Feed Speed | Max. 40 m/min |

| Spindle | 3000 – 18000 rpm with roundness <0.003 mm |

| Tool Interface | HSK 63 F |

| Process Capabilities | Grinding, Polishing, Drilling, and Milling |

| Cooling | RS technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | In the machine |

| Loading | Manual or with robot |

| Unloading | Manual or with robot |

| Grinding Capacity (e.g., 4mm glass) | Up to 60 pieces/h |

| Features | Very high flexibility, very high automation potential, unbeatable for single-piece production and small series, excellent for complex processing |

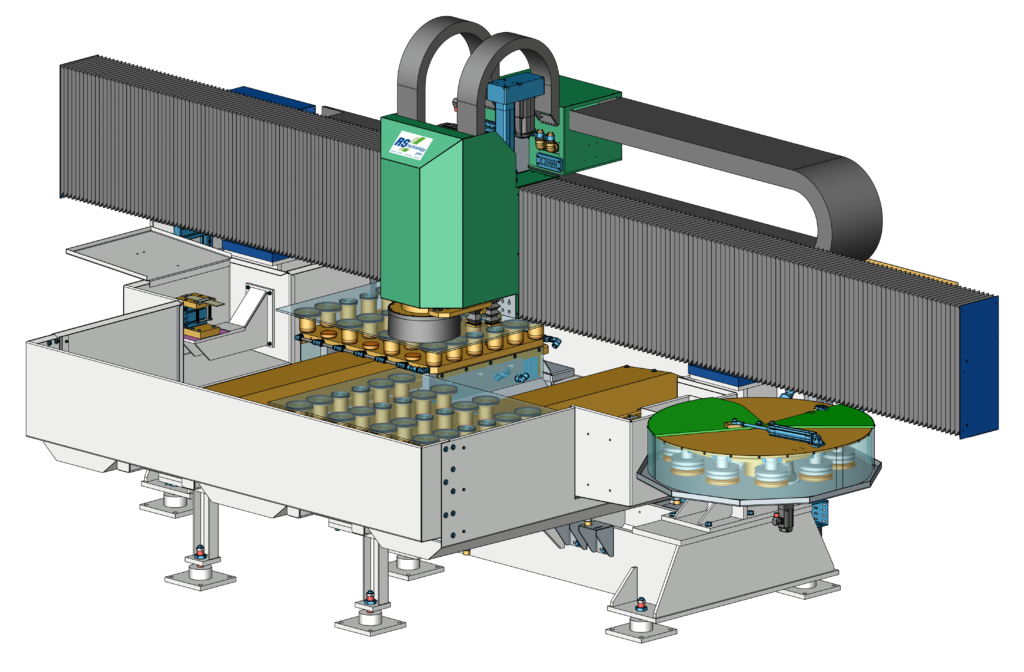

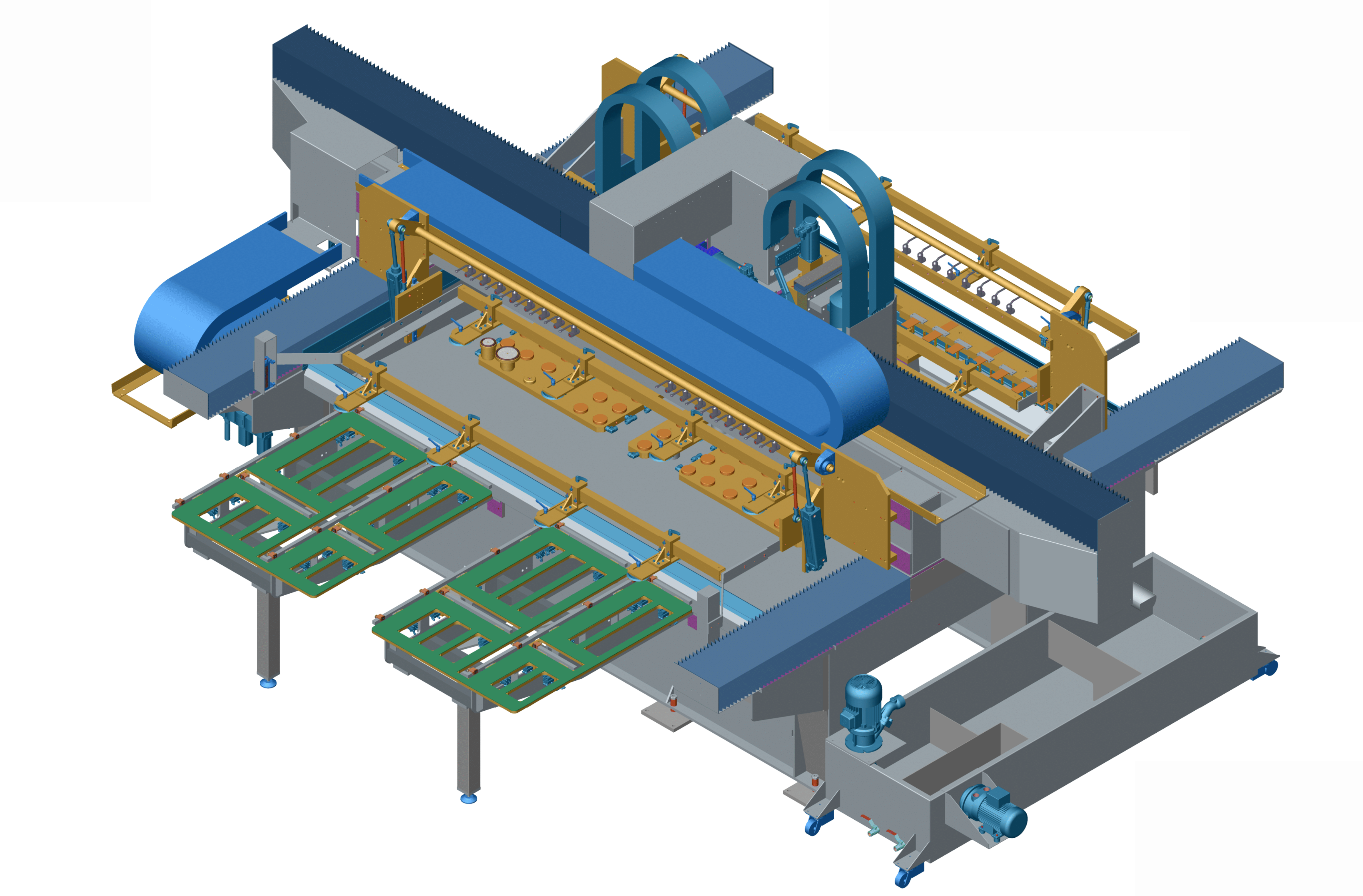

MC with Fixed Bridge

RS 89.05 – High Productivity with the Shortest Glass Change Times

The RS 89.05 is perfectly suited for companies that want to manufacture more complex components efficiently in series production.

Technical Data

Feature | Specification |

| Number of Grinding Heads | 1 or 2 |

| Min. Glass Size | 300 x 250 mm, smaller sizes upon request |

| Max. Glass Size with 2 Heads Simultaneously | 500 x 800 mm with tool max. Ø 150 mm |

| Max. Glass Size with 1 Head in Pendulum Mode | 1150 x 800 mm (small), 1200 x 1450 mm (standard), 1200 x 2000 mm (large), other sizes upon request |

| Max. Glass Size with 1 Head and Gantry Table | 2300 x 800 mm (small), 2500 x 1450 mm (standard), 2500 x 2000 mm (large), other sizes upon request |

| Glass Thickness | 1.2 to 19 mm |

| Feed Speed | Max. 40 m/min |

| Spindle | 3000 – 18000 rpm with roundness <0.003 mm |

| Tool Interface | HSK 63 F |

| Process Capabilities | Grinding, Polishing, Drilling, and Milling |

| Cooling | RS technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | In the machine or on an external positioning table |

| Loading | Manual, with robot, or with shuttle |

| Unloading | Manual, with robot, or with shuttle |

| Grinding Capacity (e.g., 4mm glass) | Up to 150 pieces/h in 1-head pendulum mode |

| Grinding Capacity (e.g., 4mm glass) | Up to 300 pieces/h in 2-head pendulum mode |

| Features | Very high automation potential, very short glass changeover times, extremely high production output |

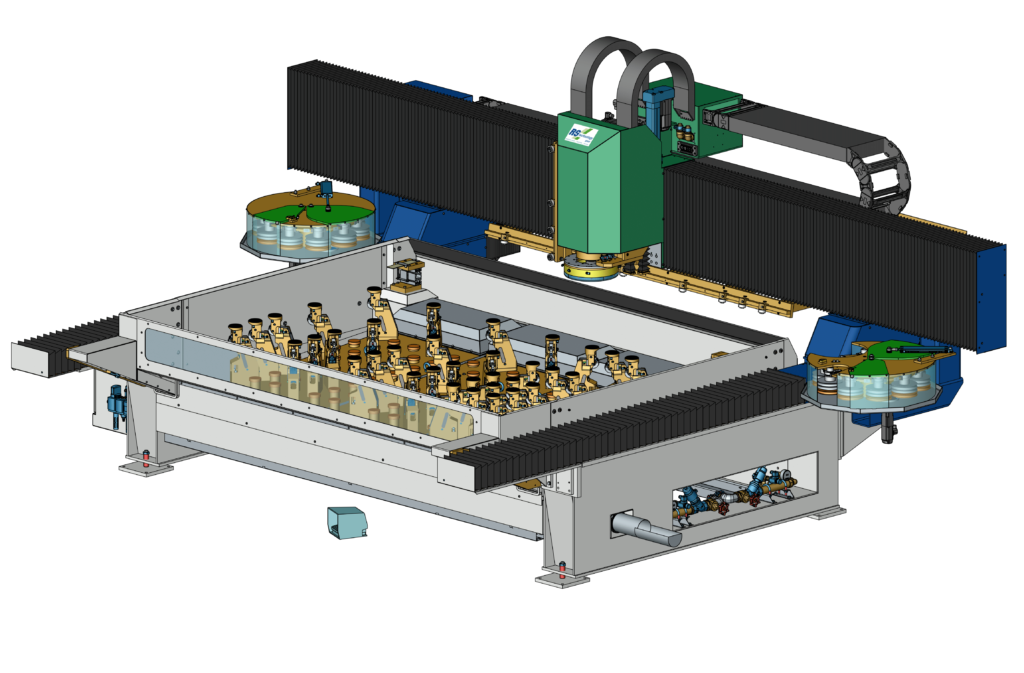

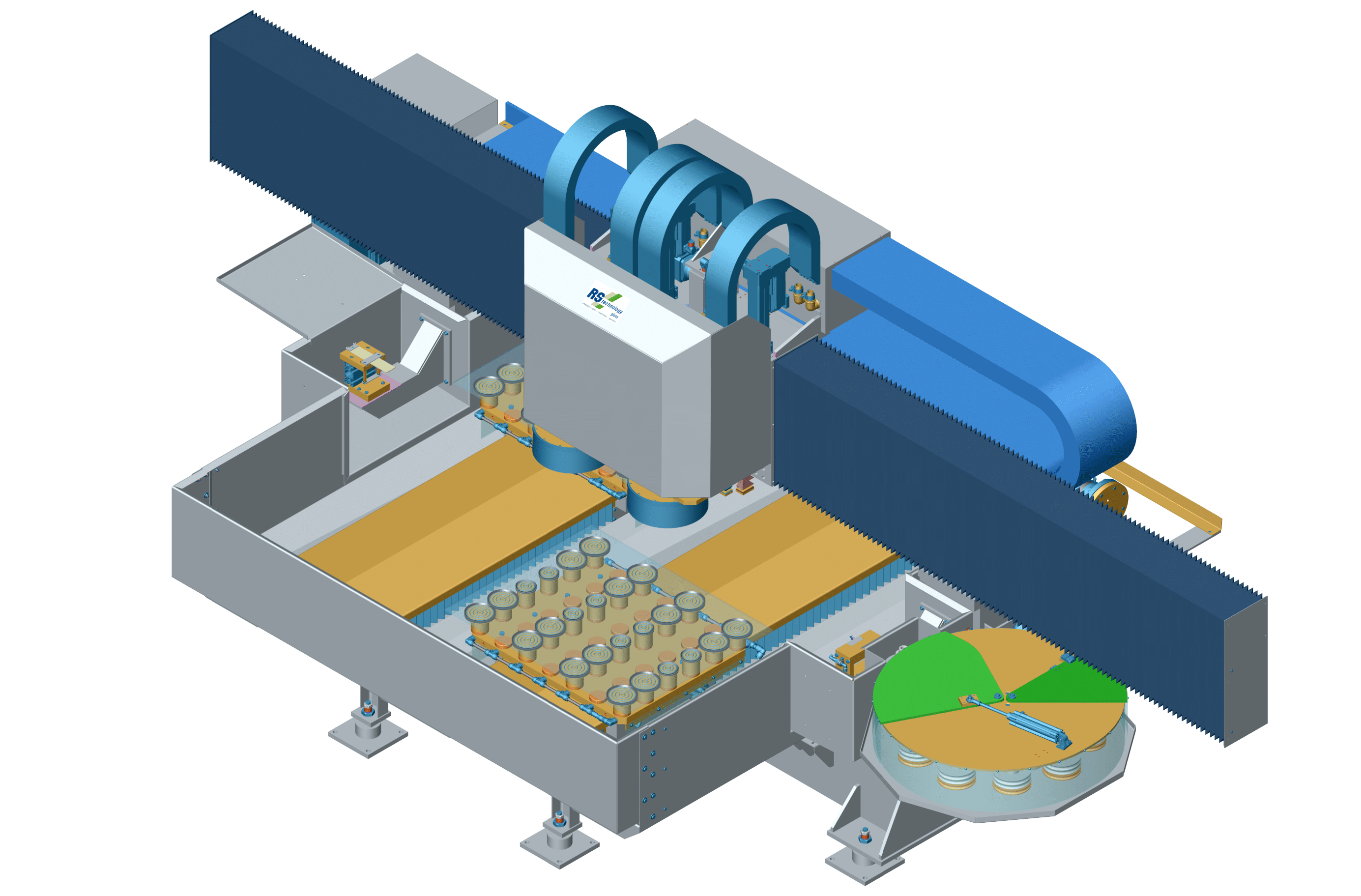

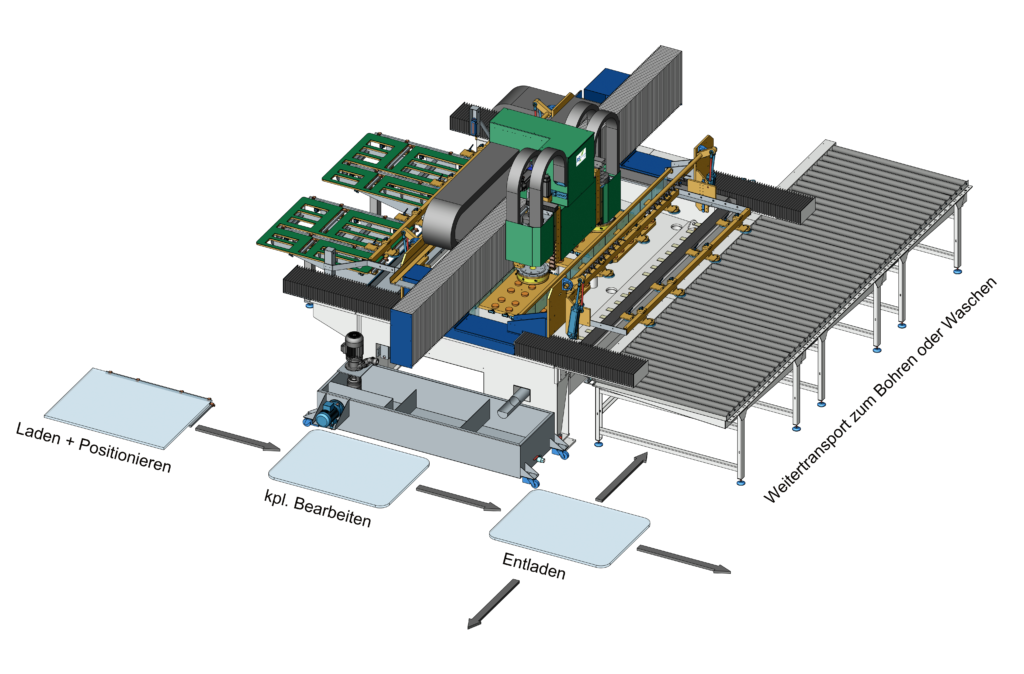

MC with Traveling Bridge In-Line-Concept

RS 8.14 FF – Highest Performance with Maximum Flexibility

The RS 8.14 FF is a machine with unprecedented possibilities. Almost anything is possible, thanks to its two grinding heads, offering high-volume production.

Technical Data

| Number of Grinding Heads | 1, 2, or 4 |

| Min. Glass Size | 300 x 250 mm, smaller sizes upon request |

| Max. Glass Size with 2 Heads Simultaneously | 1000 x 1450 mm |

| Max. Glass Size with 1 Head | 2500 x 1450 mm with tool max. Ø 150 mm |

| Glass Thickness | 1.2 to 19 mm |

| Feed Speed | Max. 40 m/min |

| Spindle | 3000 – 18000 rpm with roundness <0.003 mm |

| Tool Interface | HSK 63 F |

| Process Capabilities | Grinding, Polishing, Drilling, and Milling |

| Cooling | RS technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | Positioning table directly in front of the machine |

| Loading | Manual or with robot |

| Unloading | Automatic on roller conveyor |

| Grinding Capacity (e.g., 4mm glass) | Up to 260 pieces/h in 2-head operation |

| Features | Manual and robot loading freely applicable, suitable for both series and one-piece production, medium-sized glass handled easily in dual-head operation, large glass easily handled and positioned |

Drilling

Custom drilling solutions as C-frame or portal solutions, fully integrated into your overall concept, with automatic connection to washing, and inspection if required.

Technical Data

We offer you a solution that meets all your requirements. For more information, please contact us.

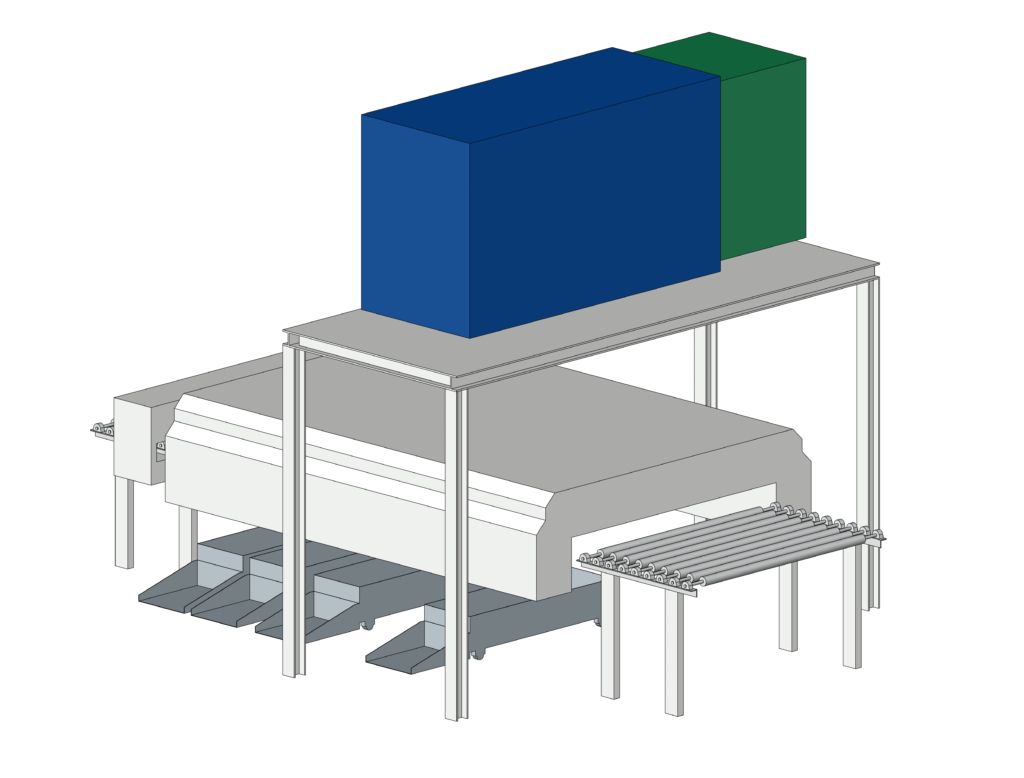

Washing

In accordance with the requirements of your surface treatment, we integrate the appropriate washing and drying system into your production line

Technical Data

We offer you a solution that meets all your requirements. For more information, please contact us.

CNC Machining with Drilling and Washing Machine

RS 12.35 – Maximum Flexibility with Highest Automation

With the RS 12.35, you can produce in series fully automatically.

Technical Data

| Number of Grinding Heads | 1 or 2 |

| Min. Glass Size | 300 x 250 mm, smaller sizes upon request |

| Max. Glass with 2 Heads Simultaneously | 500 x 800 mm with max tool Ø 150 mm |

| Max. Glass with 1 Head in Pendulum Operation (small) | 1150 x 800 mm |

| Max. Glass with 1 Head in Pendulum Operation (standard) | 1200 x 1450 mm |

| Max. Glass with 1 Head in Pendulum Operation (large) | 1200 x 2000 mm |

| Max. Glass with 1 Head and Gantry Table Operation (small) | 2300 x 800 mm |

| Max. Glass with 1 Head and Gantry Table Operation (standard) | 2500 x 1450 mm |

| Max. Glass with 1 Head and Gantry Table Operation (large) | 2500 x 2000 mm |

| Glass Thickness | 1.2 to 19 mm |

| Feed Speed | Max. 40 m/min |

| Spindle | 3000 – 18000 rpm with roundness <0.003 mm |

| Tool Interface | HSK 63 F |

| Process Capabilities | Grinding, Polishing, Drilling, and Milling |

| Cooling | RS technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | In the machine or on external positioning table |

| Loading | Manual, with robot, or with shuttle |

| Unloading | Manual, with robot, or with shuttle |

| Capacity in Grinding (e.g., 4mm Glass) | Up to 150 pieces/h in 1-head pendulum operation |

| Capacity in Grinding (e.g., 4mm Glass) | Up to 300 pieces/h in 2-head pendulum operation |

| Special Features | Very high automation potential, very short glass change times, very high production performance |

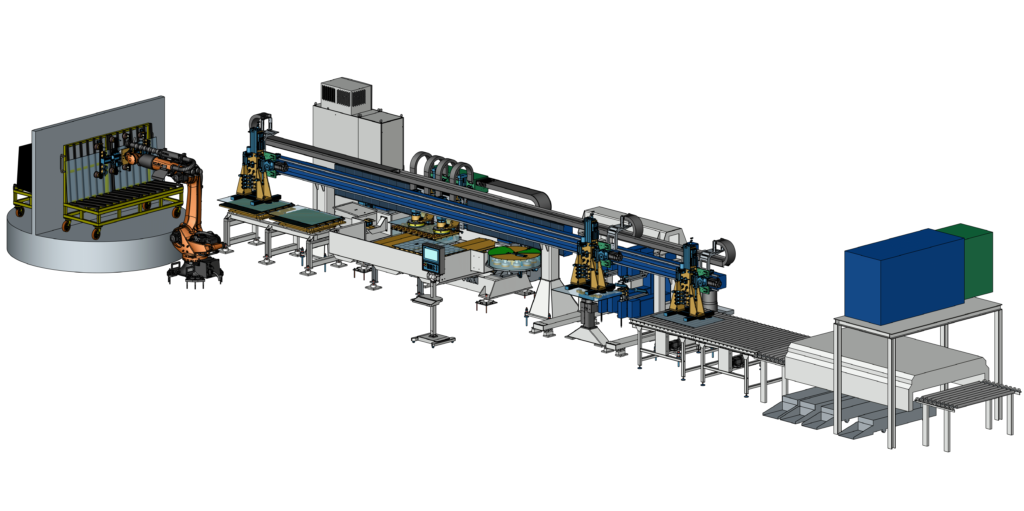

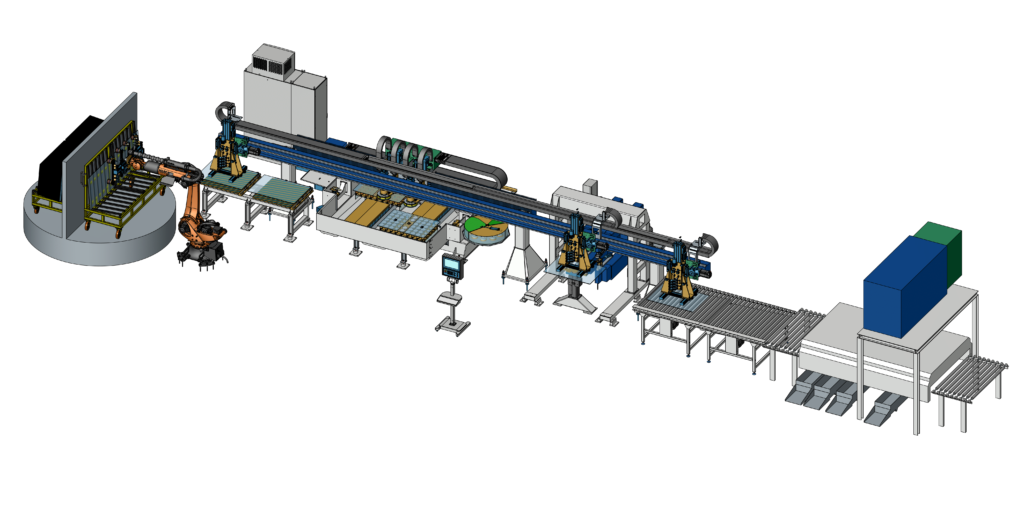

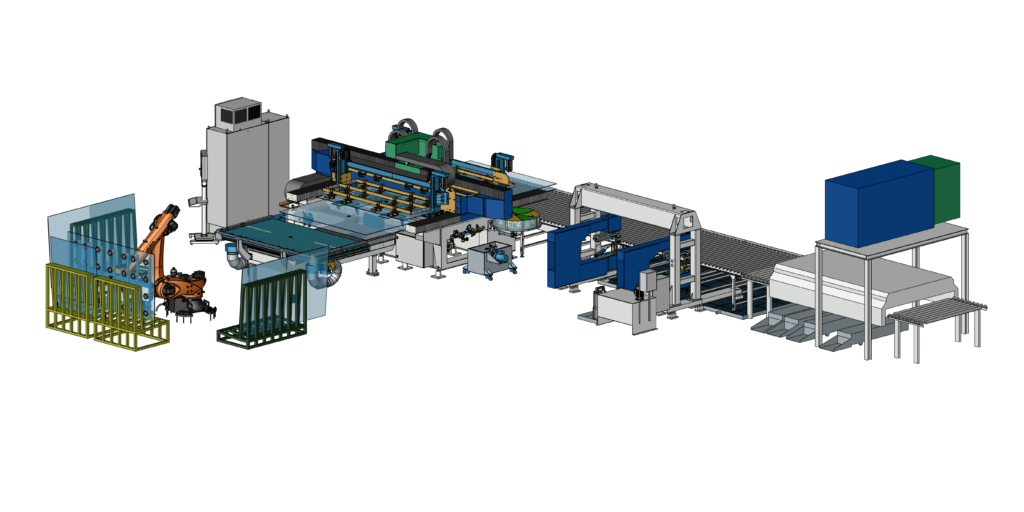

Fully Automated Shaped Glass Line

RS 12.01 – Cutting, Breaking, CNC Machining, Drilling, Washing

The RS 12.01 allows you to perform complete processing for absolute freeform glass.

Technical Data

| Number of Grinding Heads | 1 or 2 |

| Min. Glass Size | 300 x 250 mm, smaller sizes upon request |

| Max. Glass with 2 Heads Simultaneously | 500 x 800 mm with max tool Ø 150 mm |

| Max. Glass with 1 Head in Pendulum Operation (small) | 1150 x 800 mm |

| Max. Glass with 1 Head in Pendulum Operation (standard) | 1200 x 1450 mm |

| Max. Glass with 1 Head in Pendulum Operation (large) | 1200 x 2000 mm |

| Max. Glass with 1 Head and Gantry Table Operation (small) | 2300 x 800 mm |

| Max. Glass with 1 Head and Gantry Table Operation (standard) | 2500 x 1450 mm |

| Max. Glass with 1 Head and Gantry Table Operation (large) | 2500 x 2000 mm |

| Glass Thickness | 1.2 to 19 mm |

| Feed Speed | Max. 40 m/min |

| Spindle | 3000 – 18000 rpm with roundness <0.003 mm |

| Tool Interface | HSK 63 F |

| Process Capabilities | Grinding, Polishing, Drilling, and Milling |

| Cooling | RS technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | In the machine or on external positioning table |

| Loading | Manual, with robot, or with shuttle |

| Unloading | Manual, with robot, or with shuttle |

| Capacity in Grinding (e.g., 4mm Glass) | Up to 150 pieces/h in 1-head pendulum operation |

| Capacity in Grinding (e.g., 4mm Glass) | Up to 300 pieces/h in 2-head pendulum operation |

| Special Features | Very high automation potential, very short glass change times, very high production performance |

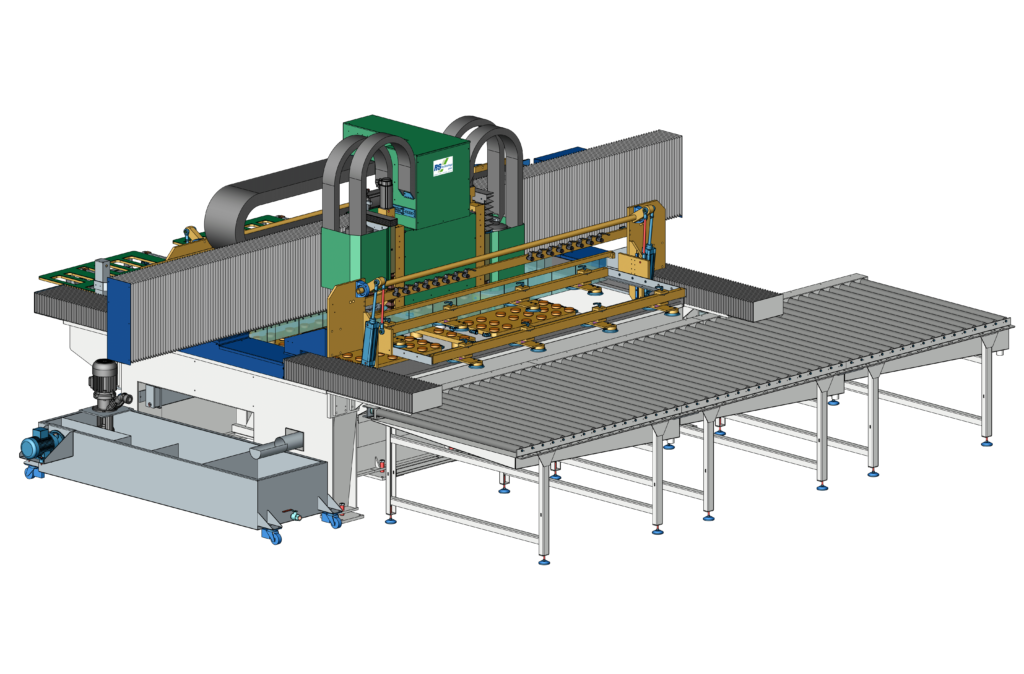

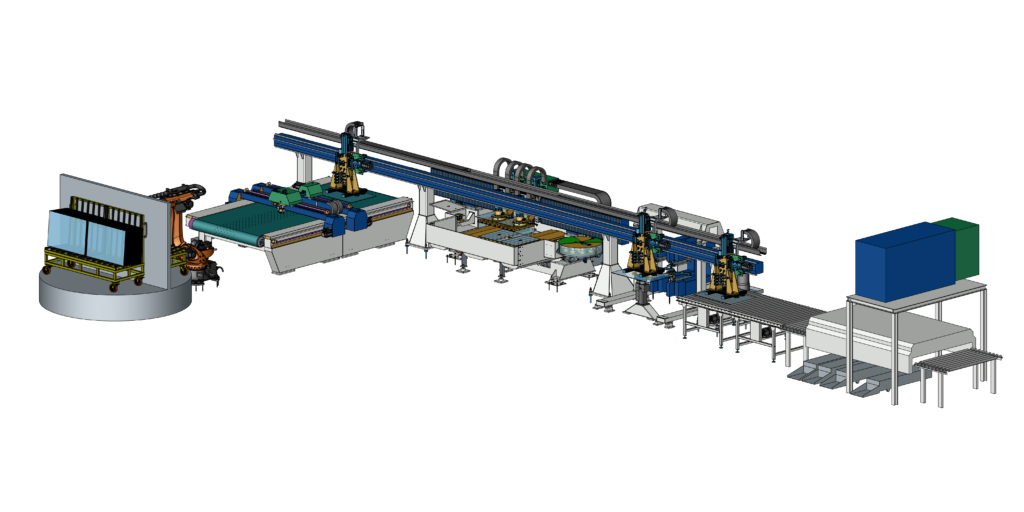

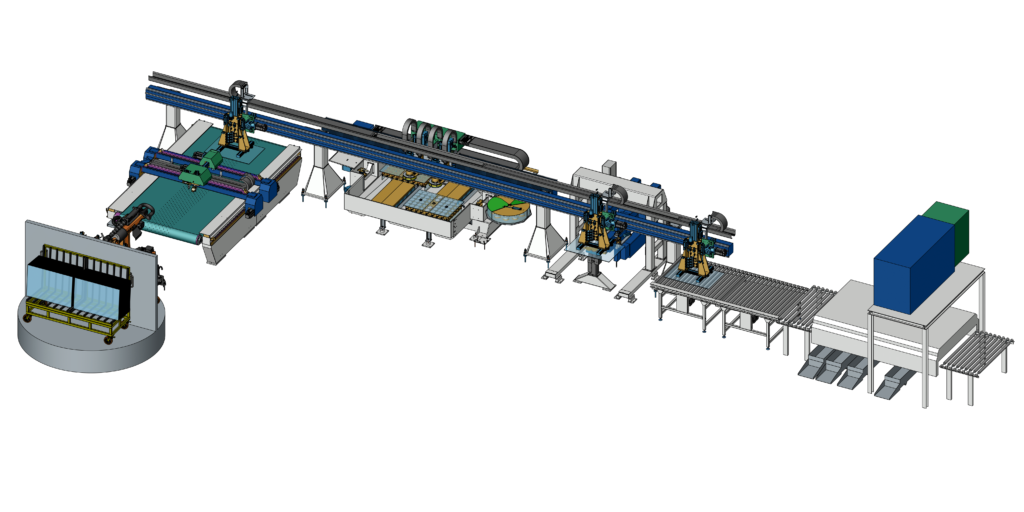

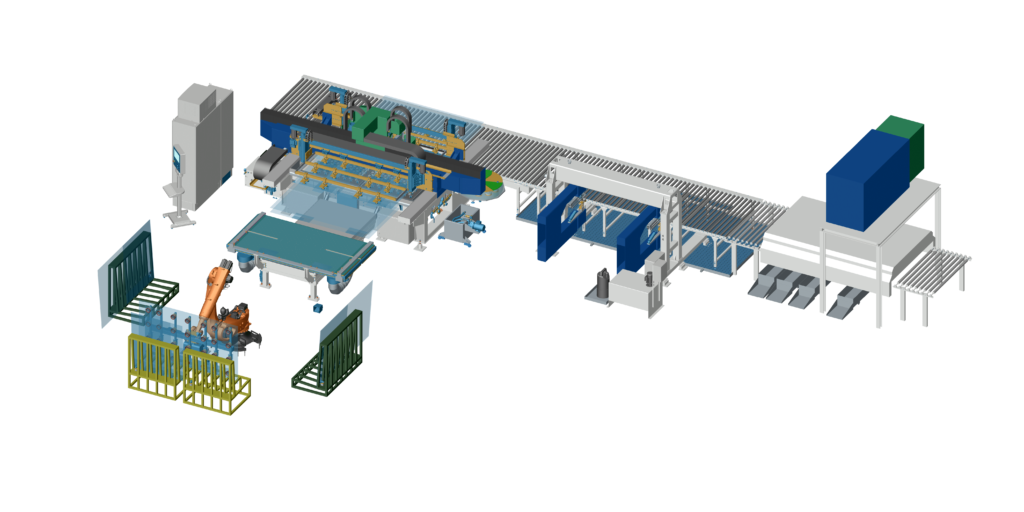

Fully Automated CNC Processing with Drilling System

RS 12.31 offers maximum flexibility with the highest level of automation.

With the RS 12.31 line, fully automated manufacturing is possible for both single-piece production and small series production with zero setup time.

Technische Daten

| Number of Grinding Heads | 1, 2, or 4 |

| Min. Glass Size | 300 x 250 mm, smaller sizes on request |

| Max. Glass Size (with 2 heads simultaneously) | 1000 x 1450 mm |

| Max. Glass Size (with 1 head) | 2500 x 1450 mm (with max. Ø150 mm tool) |

| Glass Thickness | 1.2 to 19 mm |

| Feed Rate | max. 40 m/min |

| Spindle Speed | 3000 – 18000 min⁻¹ (with <0.003 mm runout) |

| Tool Interface | HSK 63 F |

| Processing Capabilities | Grinding, polishing, drilling, and milling |

| Cooling System | RS Technology Multi-Channel Cooling, patented |

| Glass Support | Various suction systems available |

| Positioning | Positioning table directly in front of the machine |

| Loading | Manual or robotic |

| Unloading | Automatic onto roller conveyor |

| Grinding Capacity (e.g., 4mm glass) | Up to 260 pieces/hour in 2-head operation |

| Special Features | Manual and robotic loading applicable, suitable for both series and single-piece production, medium-sized glass pieces processable in dual-head mode, easy handling and positioning of large glass pieces |

| Overall | Very high flexibility |